Ammam Group’s Experience with “Edara”: Managing Details in the Tire Industry

4 Reading minutes

In some industries, the real challenge is not how many products you sell or how wide the range is, but how accurate the details are behind each item.

In the automotive tire market, a tire is never judged as a product on its own. Production date, technical specifications, and how well it fits the customer’s needs all play a direct role in the buying decision. When information is accurate, trust follows, and having that information at the right moment becomes part of the sale itself.

This daily reality was clear in the experience of Ammam Group, a company operating in a market where mistakes in details are not acceptable and delayed information is simply not an option.

That is where the story begins, the search for a system that goes beyond managing items and puts accuracy at the center of daily operations.

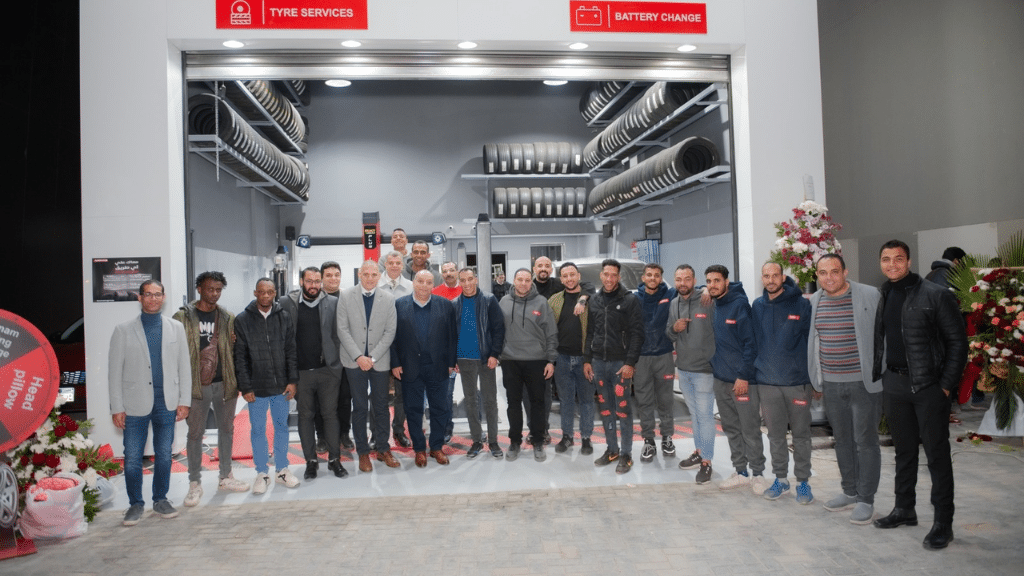

Ammam Group: A Business Built on Details

Ammam Group operates in a market where accuracy is not optional. The company offers a wide range of automotive products, including tires, batteries, oils, and car accessories, a business that depends on clear product understanding and confident communication during the sales process.

With a network of six branches, the team handles products that vary in specifications and production dates every single day. In this environment, accurate information becomes a core part of the customer experience, not just an extra detail.

As operations grew, it became clear that basic operational tools were no longer enough. The nature of the business required a clearer way to present product details, especially production dates and batch numbers, and make them easily available as part of daily work inside each branch.

When the Batch Number Becomes Part of the Sales Decision

In the tire market, a sales decision is not driven by the product alone, but by its batch number. Older batches are usually priced lower, making them an opportunity that needs to be utilized quickly, rather than left to accumulate in stock.

At the point of sale, sales representatives need a clear view of the available batches, their production dates, and the price differences that guide the selling decision. With multiple specifications and varying production dates, the batch number has become a key factor in shaping this process.

The challenge was not in recording the data, but in presenting it clearly and instantly in a way that supports sales across branches. Moving older stock also became more than an individual effort, it turned into a management decision that requires tracking sales performance and linking incentives to the ability to sell older batches alongside newer ones.

This is where “Edara” played its role. By linking batch numbers to product specifications directly within the sales cycle, the batch number shifted from being a simple inventory reference to a tool for pricing, motivation, and informed decision-making.

Detailed Work Orders: Clear Insight into Changing Details

In Edara, the work order report goes beyond listing the item itself. It reflects the real details behind each operation. By linking the item to its batch number, the report shows the specific attributes that distinguish one tire from another.

Details such as size, tread pattern, color, and technical specifications become part of the work order itself. This gives the team a clear view of what was actually sold or installed, without relying on memory or checking multiple sources.

With this level of clarity, the report is no longer just an operational document. It becomes a practical review tool that helps ensure the work delivered matches what was agreed on, in a business where small differences matter.

Clearer Operations Across All Branches

By standardizing how tires are displayed in Edara, all branches now work with the same level of clarity, regardless of product variations. Core specifications and detailed attributes, including the batch number, appear consistently across the system, without differences in description or reliance on individual judgment.

This consistency reduced confusion between similar items, especially products that may look alike but differ in important details. It also made daily operations smoother, helping teams access the right information quickly, without extra checks or repeated confirmations.

The result was more controlled operations and stronger alignment across branches, directly improving the quality of service delivered to customers.

Conclusion: When the System Fits the Product, Not the Other Way Around

Ammam Group was not looking to change systems just for the sake of change. The goal was to reach a higher level of accuracy that truly fits a business built on details.

With clearer operations across branches, information shifted from something that required searching and double-checking to something instantly available within the daily workflow, serving both the team and the customer without added complexity.

This experience shows that an effective system is not one that forces a single model on every business, but one that adapts to the nature of the product and provides tools that reflect its real details. In Ammam Group, accuracy became part of the service itself, not a separate step after it.

Related articles

One Month, One System, Endless Clarity: Forma Dimora’s Journey with “Edara”

In their New Cairo office, Forma Dimora's partners faced mounting challenges despite meticulous attention to detail. Excel spreadsheets created inventory mismatches, cost distribution errors, and accounting discrepancies that defied resolution.…

How Edara Optimized Eloroby’s Operations

Numbers tell a story, but only if you know how to read them. At Eloroby, inventory mismatches, untracked import costs, and disconnected warehouses were daily challenges, slowing operations and limiting…

“El Shorouk” and “Edara”: A Journey Toward Clearer, Smarter Data Management

In a market filled with countless similar models and product variations, precision in management becomes the defining line between operational chaos and seamless efficiency. Inside a busy electronics mall, a…