How Mega Top Rebuilt Its Operations with Edara’s Cloud ERP?

3 Reading minutes

In the security systems industry, success isn’t just about high-quality cameras or diverse products — it’s about operational precision.

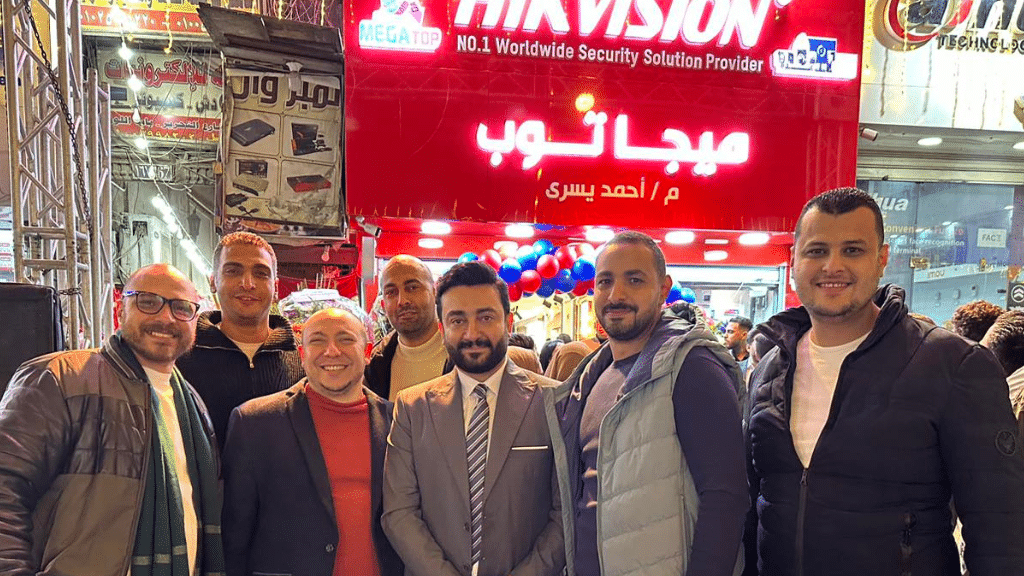

Mega Top recognized this early on. As an authorized distributor of leading brands in surveillance, attendance systems, smart home tech, and networking equipment, the company quickly made its mark.

But as operations expanded, traditional management tools fell short. Scattered data and slow oversight became major hurdles.

To keep pace, Mega Top turned to “Edara” — a cloud ERP that unified branches, tracked inventory in real-time, and centralized control.

The Hidden Cost of Disconnected Operations

Despite Mega Top’s growth, its previous internal system lacked the agility to meet market demands.

Branches and warehouses operated in silos, making basic scenarios—like invoicing at HQ and fulfilling from another location—difficult to execute.

Serial number tracking was also missing, complicating warranty cases, replacements, and high-value order reviews.

It became clear: real progress required a cloud-based solution with full visibility and precise control.

Growth vs. Reality: When Change Becomes Inevitable

Despite Mega Top’s expansion, its internal system remained disconnected from day-to-day operations. Branches and warehouses operated in isolation, with no real-time data sharing or centralized inventory oversight.

Routine tasks became unnecessarily complex — issuing an invoice from one location and fulfilling it from another was far from seamless.

Worse yet, the lack of serial number tracking posed serious risks. In a hardware-driven industry, where warranties, maintenance, and replacements hinge on exact serials, traceability is non-negotiable.

As operations grew and products multiplied, continuing with the old setup was no longer viable. Mega Top needed a system that unified branches, enabled real-time tracking, and brought full visibility — a transformation made possible with Edara.

A Smarter Start: How Mega Top Transformed Branch Operations?

Switching to Edara wasn’t just about replacing a system — it was about rebuilding Mega Top’s entire operational cycle. Over three months, the company began restructuring processes step by step, starting with branches and warehouses.

Serial number tracking was rolled out gradually, allowing the team to adapt smoothly before moving to full implementation — ensuring every device could be traced from entry to delivery.

A hybrid workflow was also introduced: some steps managed manually, others automated, reflecting the real-world complexity of branch-level sales.

The result? A flexible, market-aligned operation with real-time stock visibility and centralized invoicing, fulfilled from any branch.

Reserved but Invisible: Solving the Stock Allocation Puzzle

In Mega Top’s business model—where some orders require approvals or are fulfilled as bulk deals—tracking reserved stock is critical.

Items might physically exist in the warehouse, but if they’re already allocated to pending sales orders, they’re effectively unavailable.

This created the need for clear visibility: Which stock items are reserved? For which orders?

With Edara, the finance team gained access to a dedicated report showing real-time reserved items, their corresponding warehouses, and linked sales orders.

No more manual checks or scattered reports — just faster decisions, better accuracy, and smarter inventory control.

Clear Visibility, Defined Roles: Permissions That Make Sense

As Mega Top expanded, it became crucial to control who sees what. With multiple branches and warehouses, giving every user full access would only create confusion.

That’s where Edara’s “Ignore warehouse permissions in reports” feature proved invaluable — allowing management to tailor visibility so each team member sees only what’s relevant to them.

The result? Clearer roles, reduced clutter, and greater trust in the data each user works with.

One System, One Vision: Mega Top’s Operational Overhaul

Mega Top’s journey with Edara wasn’t just a system switch — it was a deliberate move from fragmented operations to a fully connected workflow, managed from a single, central point.

What was once separate warehouses and branches became a seamless cycle: invoices issued at HQ, items dispatched from any branch, with precise serial tracking, real-time inventory visibility, and clearly defined user permissions.

Every process gained structure, every decision was backed by data — and with Edara, growth became a controlled, confident step forward.

Related articles

From Chaos to Control: How “Fufa” Streamlined Fashion with “Edara”?

Founded in 2014, Fufa Shop blends Egyptian cultural heritage with artisanal craftsmanship in women's fashion. Despite successful expansion into multiple physical locations and e-commerce, the brand faced hidden operational challenges…

One Month, One System, Endless Clarity: Forma Dimora’s Journey with “Edara”

In their New Cairo office, Forma Dimora's partners faced mounting challenges despite meticulous attention to detail. Excel spreadsheets created inventory mismatches, cost distribution errors, and accounting discrepancies that defied resolution.…

How “Go Plus” Organized Inventory and Accounting with “Edara”

A missing item could stall an entire deal, a mispriced product might lead to an unexpected loss, and an unidentified balance could open the door to endless confusion. In the…